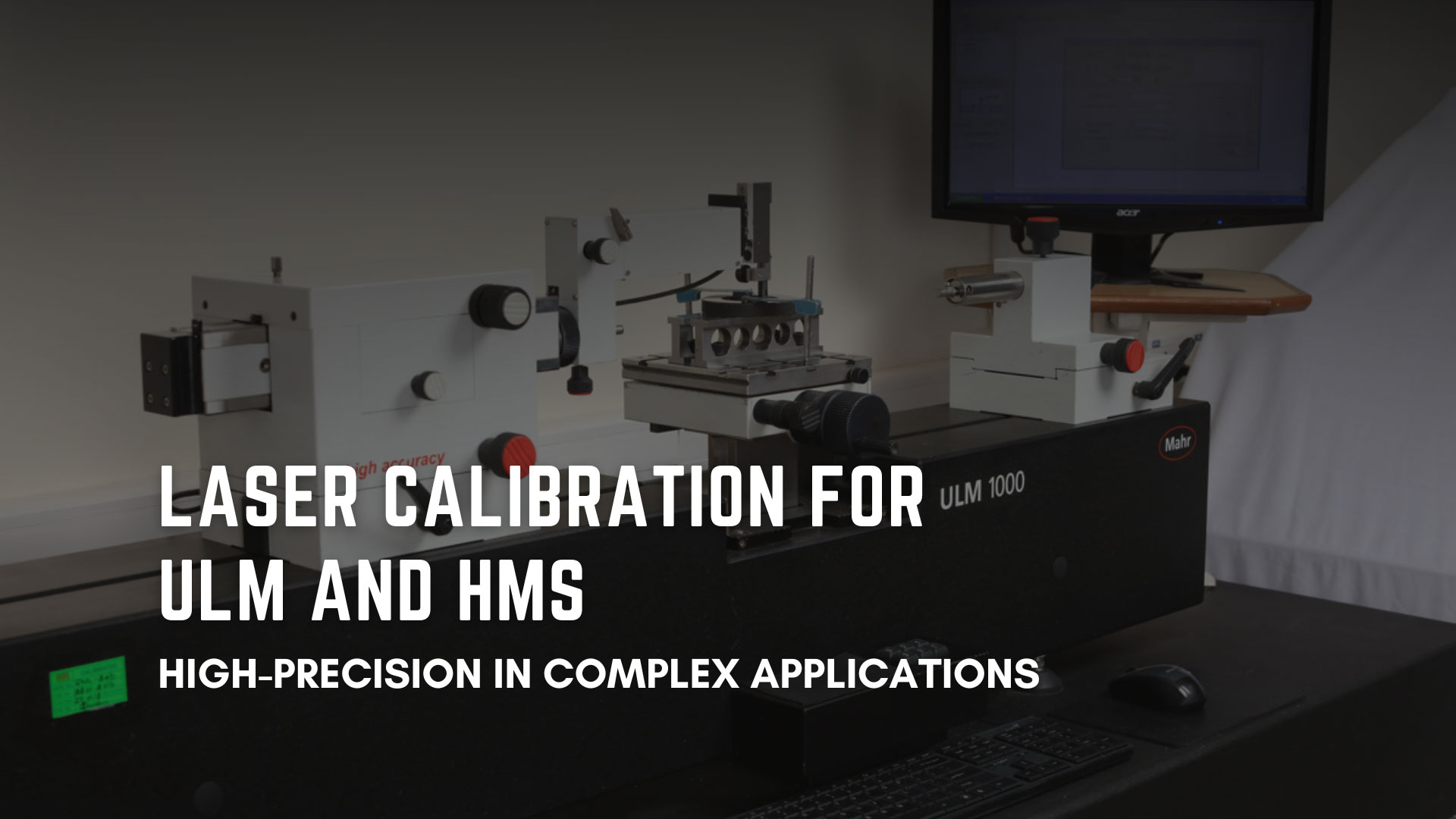

Laser Calibration for ULM and HMS – High Precision in Complex Applications

Every micron in precision manufacturing makes a difference. ULM and HMS machines are precision-designed, especially for applications that require precise accuracy to match the complexity of aerospace or medical application components. This blog explains how laser interferometry helps ULM and HMS machines and what makes proper calibration important in these highly specialized machines for efficient usage.

Overview of ULM and HMS Machines

- ULM Machines: These machines focus on achieving ultra-high precision in machining and are often used for applications like aerospace, optics, and medical devices. They require extremely tight tolerances.

- HMS Machines: HMS Machines are Designed for high-speed machining. They prioritize speed and efficiency while maintaining accuracy. They are commonly used in production environments where quick turnaround is essential.

The Importance of Laser Interferometer Calibration

The calibration of ULM and HMS machines using laser interferometry ensures that such machines yield reliable, quality outputs. Below are some of the key benefits of the laser calibration to these highly specialized machines:

- Accuracy: In order to close the tolerances required for critical applications, laser calibration allows ULM machines to establish the precision needed to address the expectations of high-stakes industries.

- Repeatability: For production environments, consistency is key. Calibrating machines with laser interferometers enables repeatable accuracy over time, supporting mass production with reliable output.

- Error Correction: The errors are minimized by laser calibration because errors are identified, and misalignments are corrected before they develop into costly or time-consuming problems.

Enhancing Machine Performance and Reliability

Incorporating laser calibration into routine maintenance ensures that ULM and HMS machines meet the stringent standards of modern manufacturing. With laser interferometers, calibration lab adjust these machines to deliver peak performance, enhancing both productivity and product quality. This calibration is vital for maintaining high standards in sectors where precision is not just a goal but a necessity.