In precision manufacturing and engineering, accuracy is not only vital—it's paramount. Whatever you're manufacturing—be it automotive components, aerospace parts, or precision devices a minute dimensional discrepancy can create major problems. This is where the role of Slip Gauge Calibration comes in.

As a core practice in mechanical calibration, slip gauges (gauge blocks) are fundamental instruments for ensuring the accuracy of measurement instruments. By keeping your slip gauges properly and frequently calibrated, you're establishing the standard for high-quality and consistent measurements in your processes.

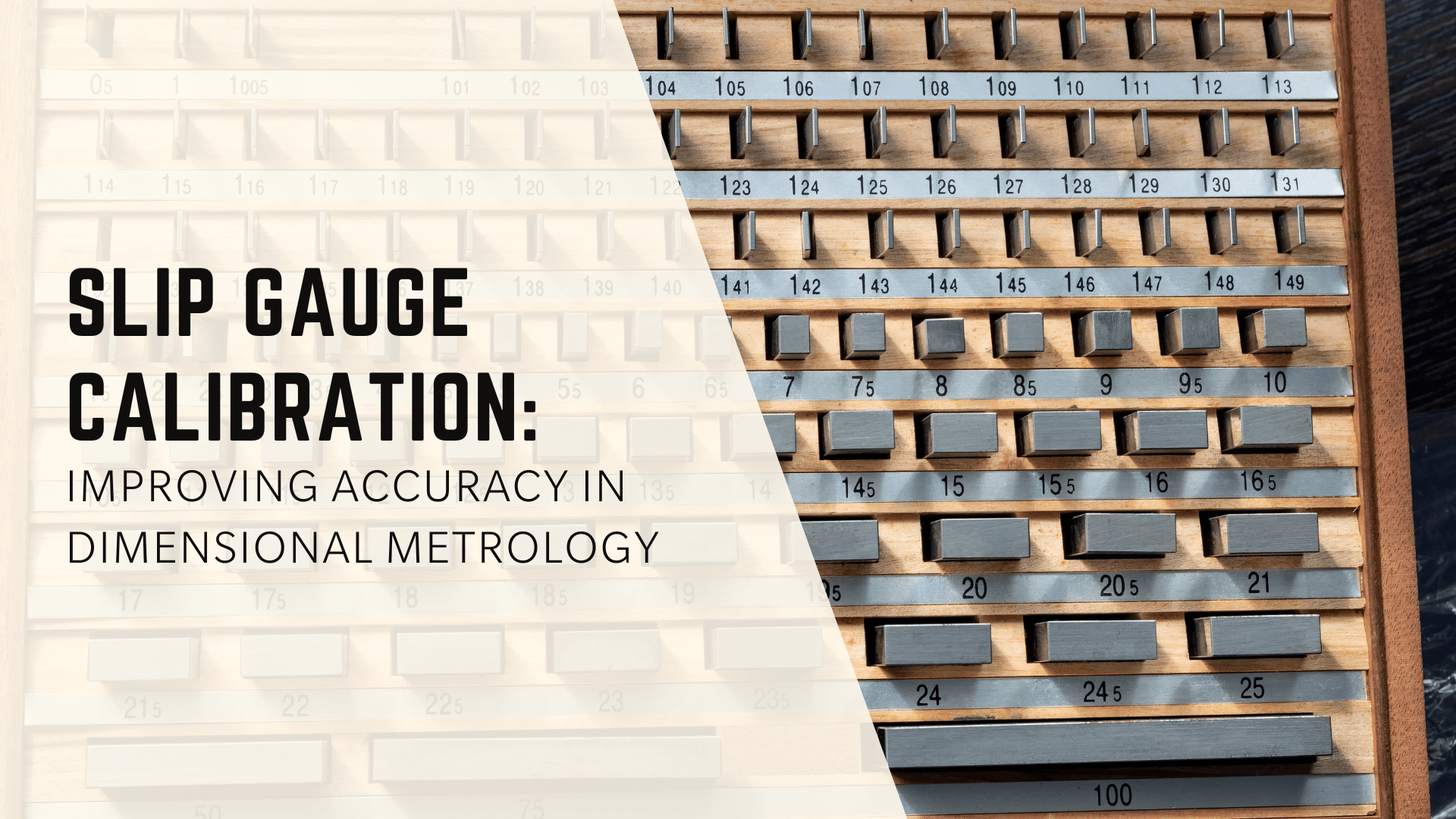

Slip Gauge Calibration is the process of comparing the physical length of slip gauges to a national or international standard. Precise ground metal blocks made typically from steel, ceramic, or carbide and employed to standardize other gauges such as micrometers, vernier calipers, and dial indicators are used during calibration.

Slip gauges, over a period of time, can become less accurate because of repeated use, wear and tear, or external factors. Therefore, it is essential to have regular mechanical calibration and Dimensional calibration services from professionals to check and regain their accuracy to ensure that they continue to meet tolerance standards.

1. Provides Accuracy in Measurements

Slip gauges serve as reference standards most of the time. If they are not accurate, all measurement tools calibrated against them are not accurate as well. Periodic Slip Gauge Calibration prevents this from happening by keeping your entire measuring system intact.

2. Facilitates Reputable Mechanical Calibration

Tools employed in mechanical calibration predominantly depend on reference tools such as slip gauges. By keeping your slip gauges under control, you ensure that all the downstream equipment and processes have the requisite level of precision and consistency.

3. Conforms to Industry and ISO Standards

Numerous industries are subject to stringent quality and compliance standards. Accredited Dimensional calibration services offer traceable calibration certificates that ensure conformity to ISO standards, customer audits, and regulatory inspections.

Opting for specialized Dimensional calibration services ensures that your slip gauges are calibrated using high-precision instruments in temperature- and humidity-controlled environments. Certified labs also provide complete documentation and traceability, which is critical for quality control and audits.

These services often include:

Dimensional metrology is all about precision, and there is no possible room for error. Slip Gauge Calibration is fundamental for accurate measurements and quality assurance for any engineering setup. By investing in an expert Dimensional calibration service and maintaining a consistent mechanical calibration schedule, you’re doing much more than keeping compliance; you’re fostering a culture of precision, reliability, and trust.